As graphene finds increasing applications across various fields, achieving high-quality, efficient, and controllable growth on non-metallic substrates has become a key research focus. Particularly in areas such as electronic devices, thermal management materials, and heating elements, graphene is highly sought after for its exceptional electrical and thermal conductivity. However, growing graphene on non-metallic substrates poses significant challenges, including high nucleation density and low-quality films.

To address this, a research team from Beijing Graphene Institute (BGI) and Peking University, led by Academician Liu Zhongfan, has developed an innovative Pre-Melted Substrate Enhanced Selective Etching (PSE) strategy, which significantly improves the growth quality of graphene on non-metallic substrates such as glass fiber.

Challenges in Graphene Growth

Graphene, a two-dimensional material composed of carbon atoms arranged in a honeycomb structure, exhibits remarkable electrical, thermal, and mechanical properties. However, growing high-quality graphene on non-metallic substrates remains a major challenge. Traditional chemical vapor deposition (CVD) methods rely on catalytic metal substrates like copper or nickel, which facilitate carbon decomposition and graphene growth. In contrast, non-metallic substrates, such as glass fiber, lack catalytic activity, resulting in poor graphene growth quality.

One of the main issues during graphene growth is the presence of high-energy sites (such as defects) on the substrate surface, which serve as nucleation points. This leads to excessive nucleation density, smaller graphene grains, and higher defect levels. Conventional approaches to improve graphene quality often involve external metal catalysts or auxiliary techniques, which can introduce contamination or residual catalysts.

The PSE Strategy: A Breakthrough Solution

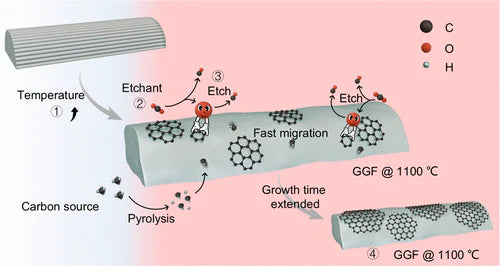

To overcome these challenges, the research team developed the Pre-Melted Substrate Enhanced Selective Etching (PSE) strategy. This approach introduces a pre-melted substrate and a carbon dioxide (CO₂) etching agent during the graphene growth process. The combination of these two factors selectively removes excessive nucleation points near the substrate, reducing nucleation density and facilitating the growth of large, high-quality graphene grains.

During the CVD reaction, the glass fiber substrate undergoes pre-melting, reaching a semi-liquid surface state. In this state, the substrate allows for easier charge transfer, which promotes carbon decomposition and accelerates graphene growth. Simultaneously, CO₂ acts as a mild oxidative etching agent, selectively removing excess nucleation sites near graphene domains. This process significantly reduces nucleation density and promotes the formation of large-area, high-quality graphene.

Performance of PSE-Grown Graphene

Graphene grown using the PSE strategy exhibits superior properties:

- Larger Graphene Grains: The maximum grain size reaches 1 micron, significantly larger than graphene grown using traditional methods.

- Reduced Defect Density: The ID/IG ratio is as low as 0.13, indicating high crystal quality.

- Enhanced Electrical Conductivity: The electrical conductivity of PSE-grown graphene is three times higher than that of conventionally grown graphene.

- 7X Longer Durability: Graphene produced with PSE demonstrates superior stability, making it particularly suitable for thermal applications.

The PSE strategy relies on precise control of the substrate surface state and CO₂ etching. Density functional theory (DFT) calculations reveal that pre-melting enhances charge transfer, allowing CO₂ to more effectively etch unwanted nucleation sites. In the pre-melted state, carbon active species (such as CH₃) exhibit lower migration energy barriers, enabling faster movement and facilitating graphene grain growth instead of unwanted nucleation. This process effectively reduces the number of nucleation sites and promotes large-scale graphene formation.

Furthermore, CO₂ etching selectively removes nucleation points near graphene domains, effectively controlling nucleation density and enhancing crystal quality.

Applications of PSE-Grown Graphene

Graphene produced using the PSE strategy demonstrates excellent electrical conductivity and thermal stability, making it ideal for heating applications. Researchers utilized this graphene to fabricate graphene-glass fiber composites (GGFF), integrating them into flexible heating devices.

The GGFF-based heating devices exhibit fast response times and uniform heat distribution, significantly outperforming conventional graphene heating materials:

- 7X Longer Lifespan: Suitable for long-duration heating applications.

- Superior Electrical Conductivity: More efficient performance for electronic and thermal applications.

Conclusion

The PSE strategy successfully addresses the challenge of growing high-quality graphene on non-metallic substrates. By leveraging pre-melted substrate treatment and CO₂ etching, the method significantly enhances graphene crystal quality and electrical properties. Graphene materials produced using this strategy exhibit remarkable performance in heating devices, highlighting their potential for next-generation electronics and smart materials.

As research progresses, the PSE strategy is expected to pave the way for scalable, high-performance graphene manufacturing, unlocking new possibilities for thermal management, flexible electronics, and advanced material applications.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.