Industrial Solutions

Glass Fiber VS Graphene Skinned Glass Fiber

Glass Fiber

- Insulation

- Low Thermal Conductivity

- High Strength

- Flexibility

- Chemical Stability

- Lightweight

Graphene-Skinned Glass Fiber

- High Electrical Conductivity

- High Thermal Conductivity

- High Strength

- Flexibility

- Chemical Stability

- Lightweight

Glass Fiber

Graphene Skinned Glass Fiber

Application Example

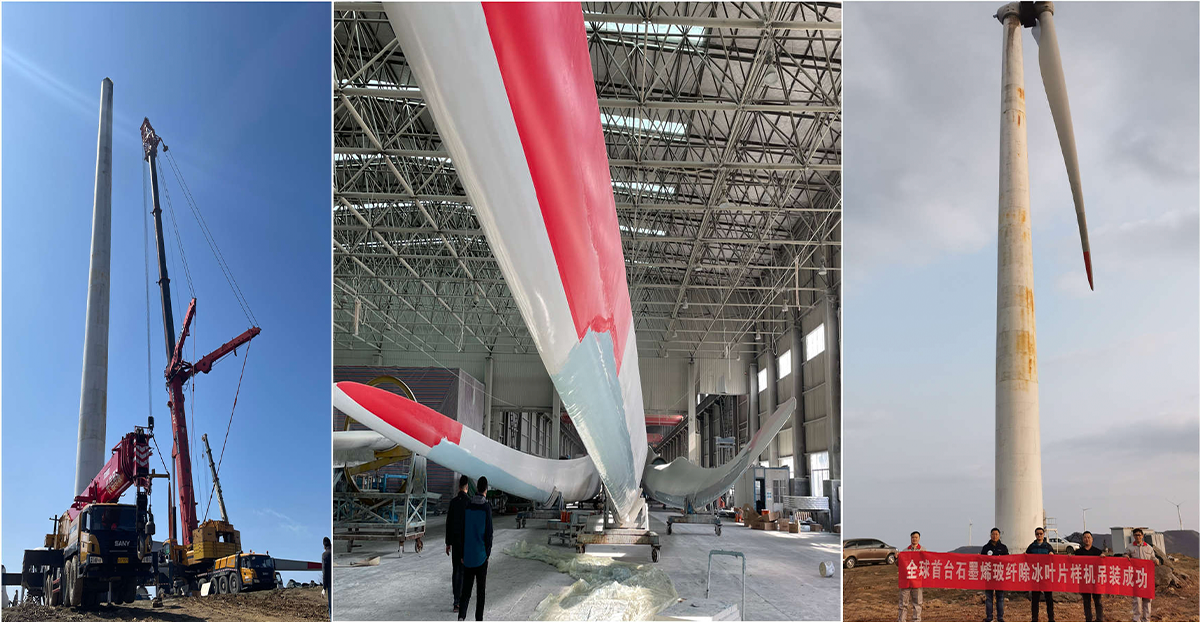

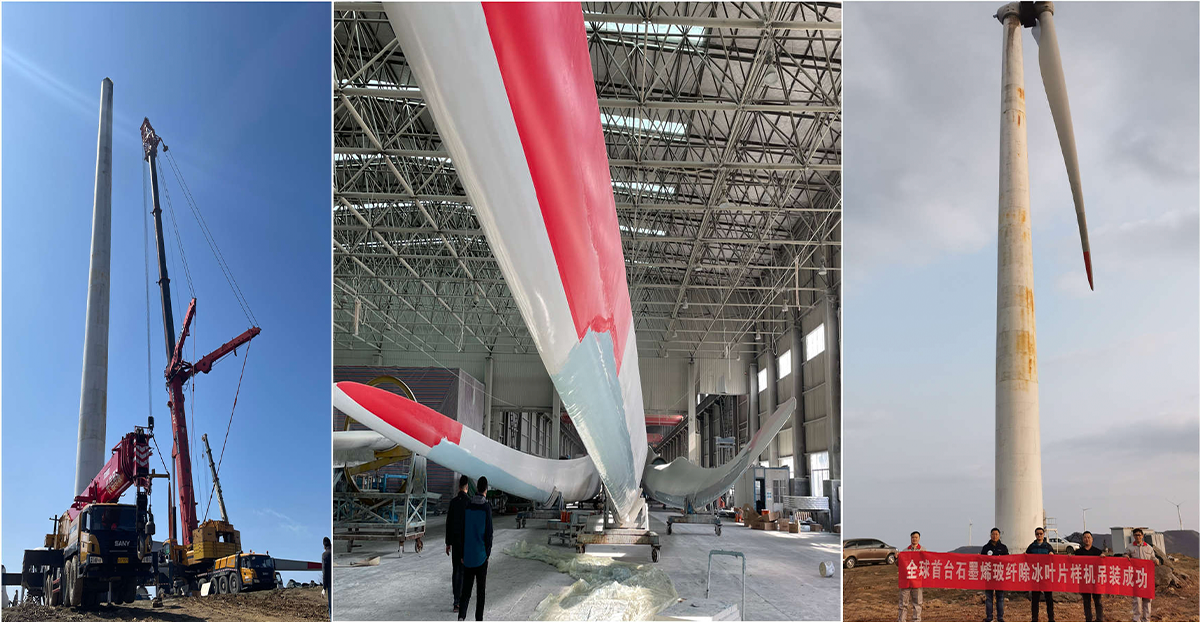

On March 14, 2023, the world's first graphene-coated glass fiber anti-icing blade prototype was successfully installed in Hunan.

- High Safety Performance

- Automated Control System

- Customizable Design

- Low Cost, High Efficiency

- Simple Construction Process

On March 14, 2023, the world's first graphene-coated glass fiber anti-icing blade prototype was successfully installed in Hunan.

- High Safety Performance

- Automated Control System

- Customizable Design

- Low Cost, High Efficiency

- Simple Construction Process

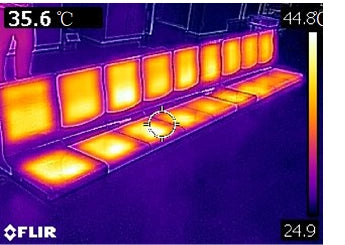

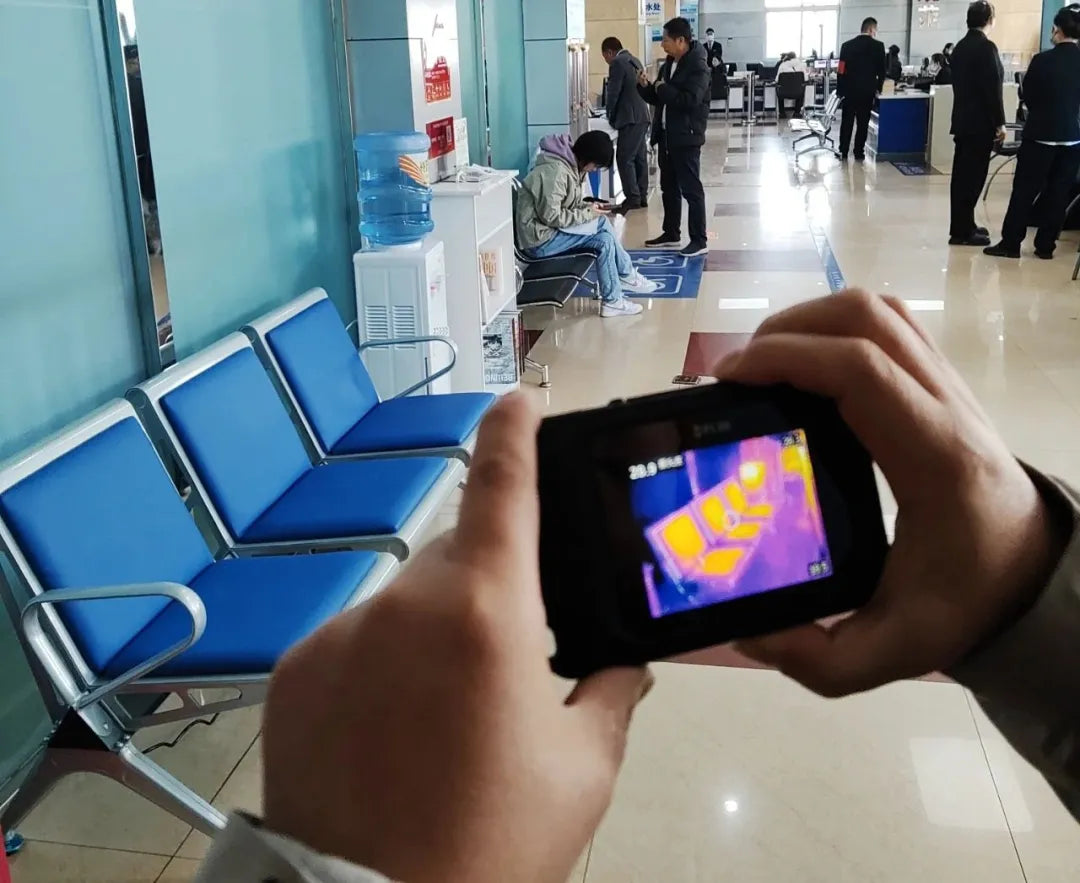

Applicable for seat heating scenarios in railway transportation, subway, airport halls, waiting rooms, etc.

- Surface heating, faster heating rate, better temperature uniformity, and more comfortable user experience. It also has better heat efficiency and more energy savings.

- Graphene-coated glass fiber material has a highly aligned 3D woven structure that forms a stronger bond with the designated seat fabric, making it more durable.

- Graphene-coated glass fiber material is produced using CVD technology, free from harmful metal emissions, and is more environmentally friendly.

- The long-term use of graphene-coated glass fiber material prevents the issue of reduced heating power over time, ensuring stable performance and longer durability.

Applicable for seat heating scenarios in railway transportation, subway, airport halls, waiting rooms, etc.

- Surface heating, faster heating rate, better temperature uniformity, and more comfortable user experience. It also has better heat efficiency and more energy savings.

- Graphene-coated glass fiber material has a highly aligned 3D woven structure that forms a stronger bond with the designated seat fabric, making it more durable.

- Graphene-coated glass fiber material is produced using CVD technology, free from harmful metal emissions, and is more environmentally friendly.

- The long-term use of graphene-coated glass fiber material prevents the issue of reduced heating power over time, ensuring stable performance and longer durability.

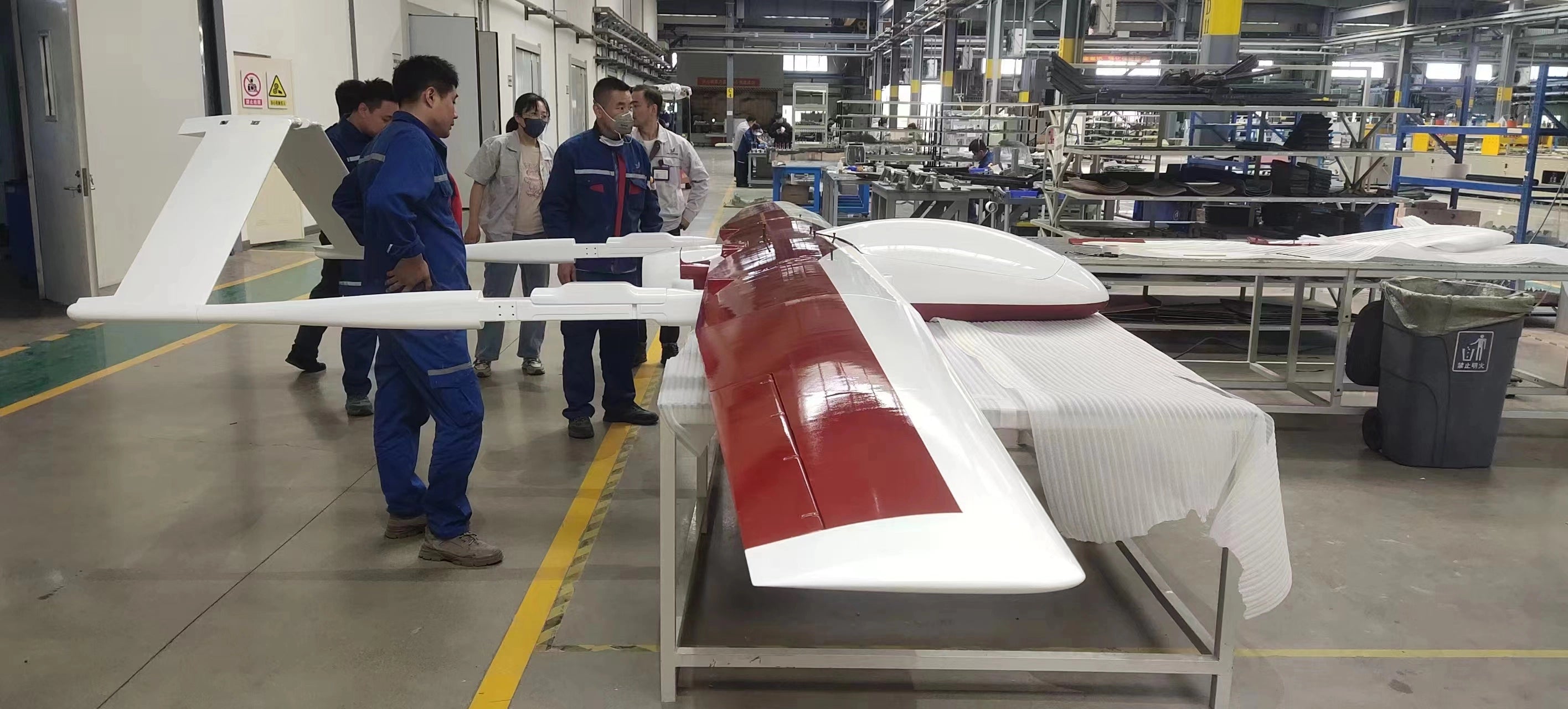

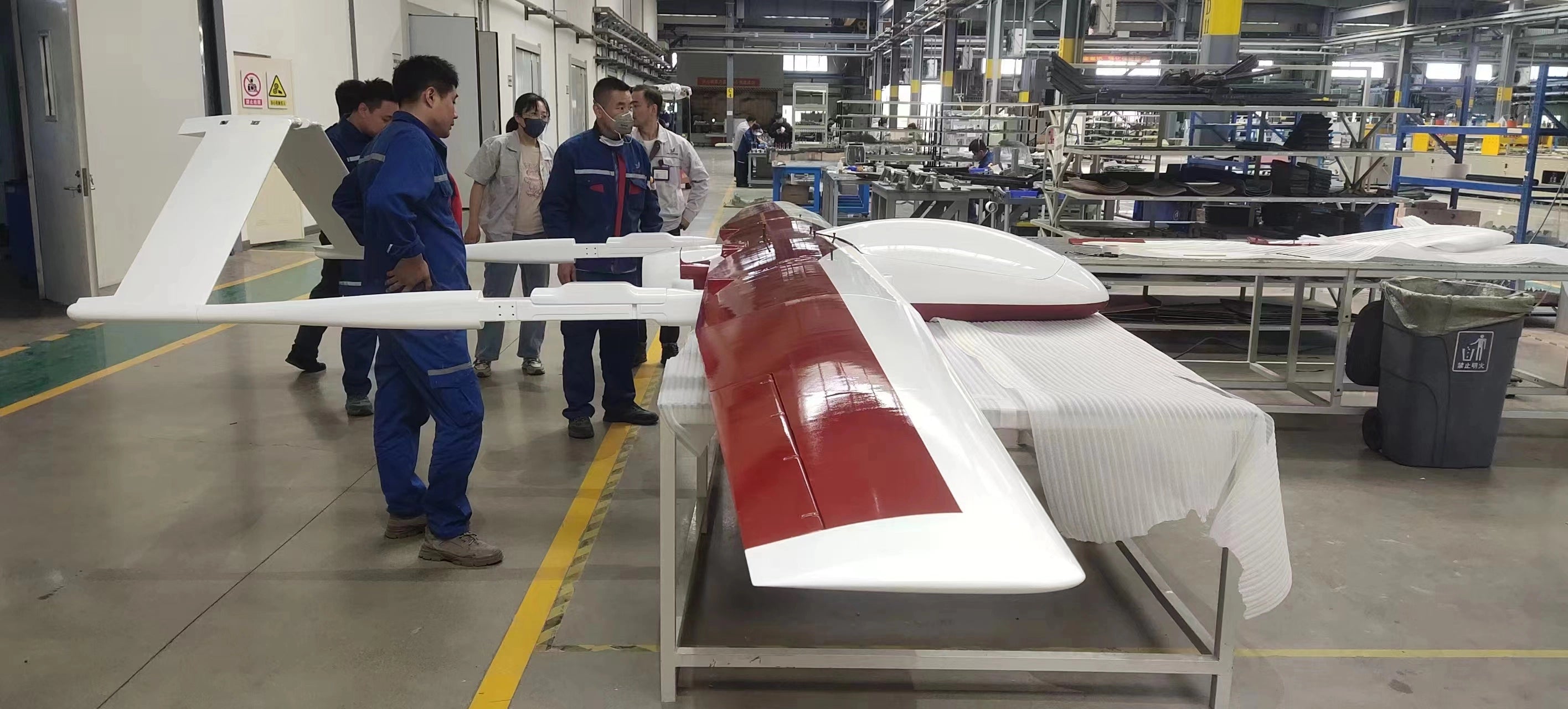

Civil drones with de-icing needs mainly fall into four categories: meteorology, inspection/patrol, mapping, and exploration. In 2023, China had over 3,200 such drones, with composite-wing drones accounting for 95% of them. Most are newly designed electric drones with an average design lifespan of 300-500 hours, meaning the de-icing materials would require replacement approximately every three years. Industrial drones are expected to maintain rapid growth over the next 5-10 years, with more new applications creating additional market opportunities and driving demand for de-icing solutions in various scenarios.

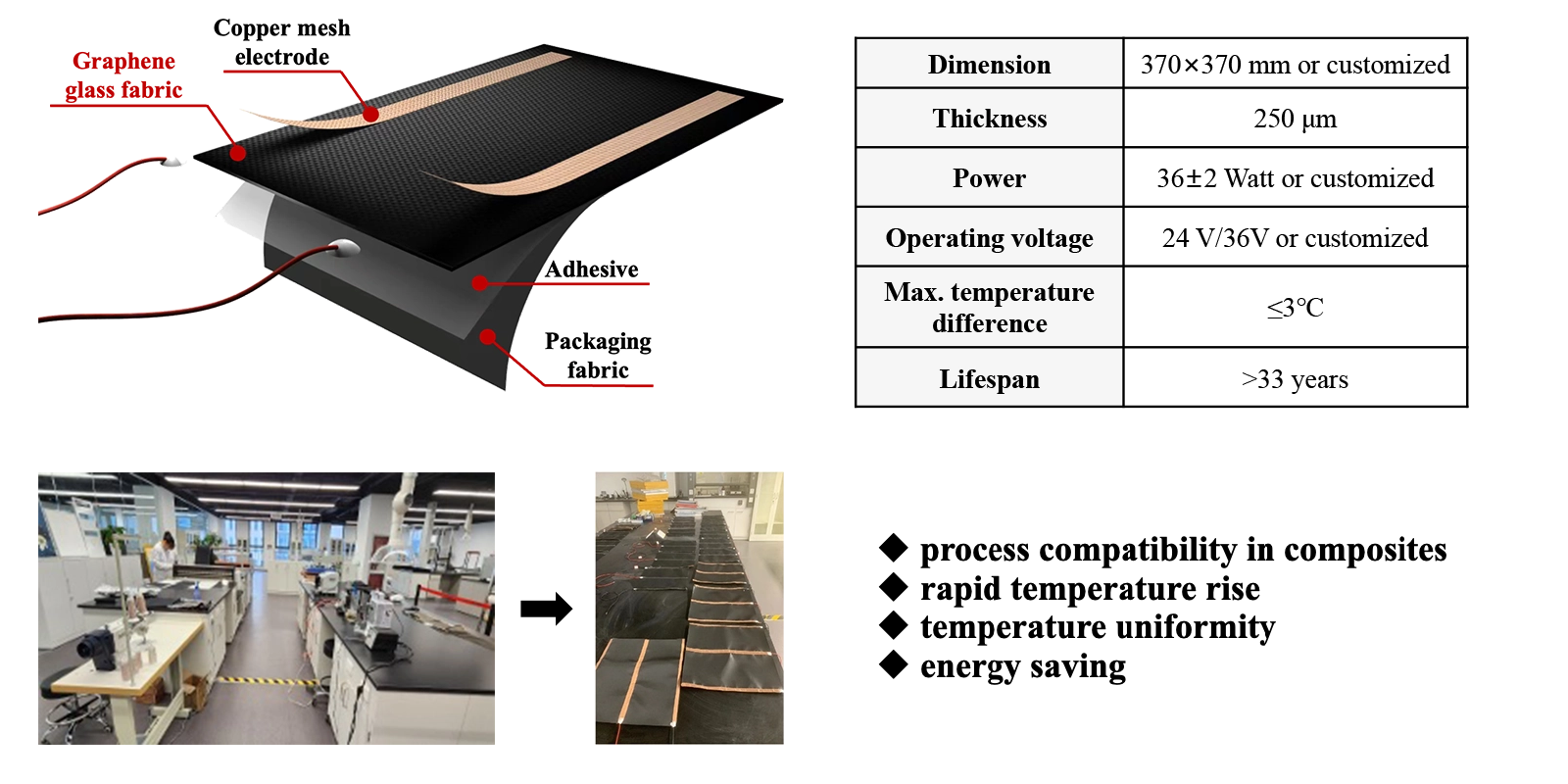

Compared to traditional hydrophobic coatings and resistance wire solutions, BGI’s Graphene Skinned materials offer significant advantages. Graphene Skinned materials are compatible with carbon fiber, glass fiber, and other materials, fitting well with autoclave processes. They bring strong core technological competitiveness and unique benefits to the de-icing field.

- Eliminates the need for pre-flight spraying and post-flight maintenance, reducing both cost and labor.

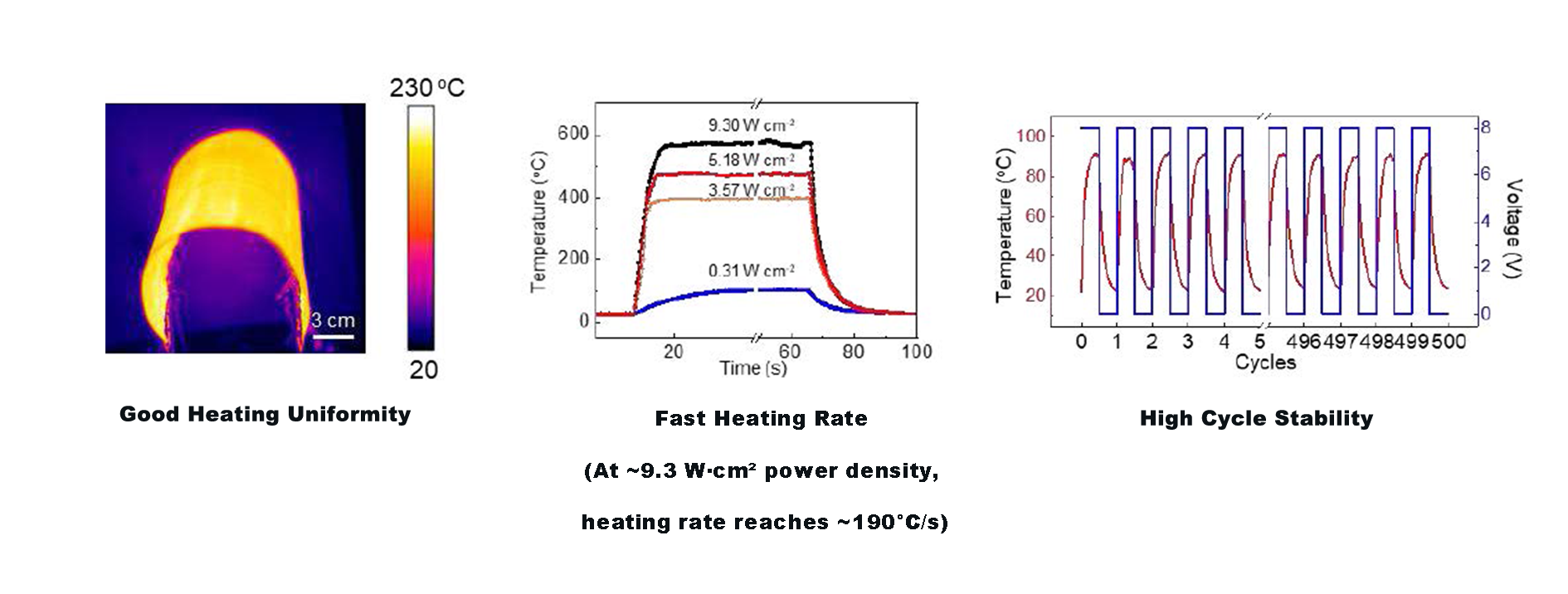

- High heating rate with excellent temperature uniformity, resulting in superior de-icing performance.

- Can be pre-installed and perfectly integrated with wing materials, offering high process compatibility and installation flexibility.

- No power decay, ensuring longer usage with stable and reliable performance.

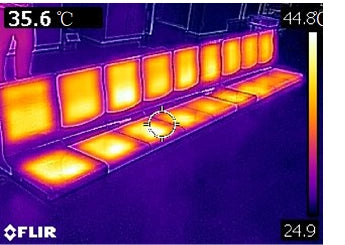

- Surface heating provides good temperature uniformity, with temperature non-uniformity less than 2%.

- Adjustable sheet resistance allows for more flexible heating solutions.

- High heating rate for better de-icing effectiveness.

- Higher electrothermal conversion efficiency, resulting in better energy savings and extended cruising time.

- Localized damage does not affect overall heating, ensuring safety and durability.

Currently, BGI is working with Xi'an Bingguo Intelligent Aviation Technology Co., Ltd. to use Graphene Skinned glass fiber to address issues of wing and propeller icing after prolonged operation in supercooled zones, marking the first entry of Graphene Skinned glass fiber into the civil drone market. BGI is also collaborating with Xi'an Lingkong to jointly develop a de-icing solution for medium and large industrial drones (manned aircraft converted to unmanned), expanding from meteorological drones into the industrial drone sector and entering new fields.

Civil drones with de-icing needs mainly fall into four categories: meteorology, inspection/patrol, mapping, and exploration. In 2023, China had over 3,200 such drones, with composite-wing drones accounting for 95% of them. Most are newly designed electric drones with an average design lifespan of 300-500 hours, meaning the de-icing materials would require replacement approximately every three years. Industrial drones are expected to maintain rapid growth over the next 5-10 years, with more new applications creating additional market opportunities and driving demand for de-icing solutions in various scenarios.

Compared to traditional hydrophobic coatings and resistance wire solutions, BGI’s Graphene Skinned materials offer significant advantages. Graphene Skinned materials are compatible with carbon fiber, glass fiber, and other materials, fitting well with autoclave processes. They bring strong core technological competitiveness and unique benefits to the de-icing field.

- Eliminates the need for pre-flight spraying and post-flight maintenance, reducing both cost and labor.

- High heating rate with excellent temperature uniformity, resulting in superior de-icing performance.

- Can be pre-installed and perfectly integrated with wing materials, offering high process compatibility and installation flexibility.

- No power decay, ensuring longer usage with stable and reliable performance.

- Surface heating provides good temperature uniformity, with temperature non-uniformity less than 2%.

- Adjustable sheet resistance allows for more flexible heating solutions.

- High heating rate for better de-icing effectiveness.

- Higher electrothermal conversion efficiency, resulting in better energy savings and extended cruising time.

- Localized damage does not affect overall heating, ensuring safety and durability.

Currently, BGI is working with Xi'an Bingguo Intelligent Aviation Technology Co., Ltd. to use Graphene Skinned glass fiber to address issues of wing and propeller icing after prolonged operation in supercooled zones, marking the first entry of Graphene Skinned glass fiber into the civil drone market. BGI is also collaborating with Xi'an Lingkong to jointly develop a de-icing solution for medium and large industrial drones (manned aircraft converted to unmanned), expanding from meteorological drones into the industrial drone sector and entering new fields.

More Possibilities

Graphene glass fabric heating components were developed for civilian use, applied in heated seats of rail vehicles, cars, stadiums, waiting halls, etc.

Data Sheet

Relevant News

BGI’s Graphene-Glass Fiber Material Revolutionizes Drone Anti-Icing Technology

Artificial weather modification has become a vital tool for advancing agriculture and ecological preservation. Since the 18th National Congress of the Communist Party of China, major policies such...

BGI Highlights Graphene Advancements at the 8th International Carbon Materials Conference 🌟

At the 8th International Carbon Materials Conference in Shanghai, Dr. Qi Yue, Researcher at the Beijing Graphene Institute (BGI), delivered a keynote presentation showcasing BGI’s progress in over...

BGI's Graphene Heated Seats Debut at Mentougou District Government Hall

On November 6, Beijing Graphene Institute Co., Ltd. (BGI) unveiled its graphene-heated seats at the Mentougou District Government Hall in Beijing. These innovative seats not only enhance the comfo...